☰ Menu

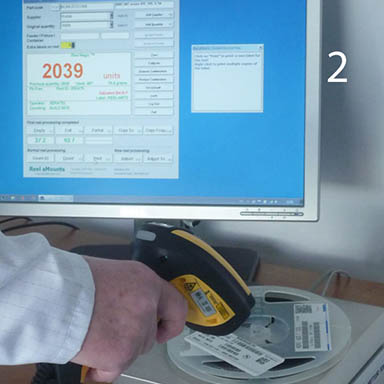

Instant (1.2 seconds) counting of reels of any size. Far faster than any other system.

Uses unique, patented, artificial intelligence (AI) pattern-matching technology.

Counts SMT / SMD parts from 01005 (metric 0402) chips on 4mm tape at 1mm pitch up to the largest IC.

Counts reels in feeders, including twin track feeders.

Counts PTH, tubes, strips, matrix trays, loose components, box build parts, 3D printing consumables as well as SMT / SMD ... in fact almost any part in any container.

Does not have problems with RFID labels.

Calculates usage and attrition and automatically passes inventory corrections to an ERP system. Corrections can reference both the work order number and the individual reel ID.

Attrition calculations can take into account both fixed and percentage allowances already built into BOMs and then generate write-off or write-on messages accordingly.

Handles family builds/combined kits, multiple reels of the same material, double-ganging, moving material between builds...

Maintains a complete inventory of all reel stock, showing both overall stock for any part and broken down by reel, supplier etc.

Number of components on the reel

Number of components on the reel

Previous quantity

Quantity used

Expected usage

Attrition

Attrition rate

Attrition cost

Attrition built into BOM

Write-on or write-off required

Manufacturer

Your part code

Manufacturer part code

Original quantity

Percentage remaining

Value remaining

Date received

Approaching use-by date warning

Past use-by date alert

Reel aMounts unique reel ID

Your reel ID/serial/licence plate

Additional user defined information such as batch number or date code

Complete history of usage for the reel

RoHS status

Moisture sensitivity and bagging instructions

Build/kit/work order used in

Placement equipment used

Feeder used

Operator performing count

Where counted

When counted

Name of count

Type of count - received, issued, returned, cycle count ...

How it was labelled

Any special instructions for this part and/or supplier

... and more

Customer defined size and layout.

Over twenty fields can be included in human readable form, bar code (1D and 2D) or both.

Automatically translates supplier part codes into your part codes.

Reads and interprets 2D bar codes in ECIA format to extract part code, date code and more.

Generates a unique traceability ID for the reel.

Passes details of all material received to your ERP system, warehouse management system and/or automated storage system.

Provides details of where the material should be stored.

Kits work orders, using a choice of methods - FIFO or best fit for remaining reel quantity.

Automatically takes attrition allowances into account.

Kits both single work orders and combined kits/family builds.

Notes and validates reels picked for a kit.

Instructs an ERP system to reserve the extra material on any reel picked for a kit, giving the quantity to be reserved, so no attempt is made to allocate it elsewhere.

Informs an ERP system that material previously reserved is now free for allocation to work orders.

Warns operators whenever a returned reel requires sealing in a moisture proof bag and/or baking.

Shows the value of material remaining on each reel, allowing low-value reel ends of plentiful material to be scrapped rather than put through the full returns process.

Labels reels with return locations to ensure that they are correctly and swiftly returned to stores.

Communicates with carousel and other automated storage systems, providing full details of material returned.

Reel aMounts reel IDs can be used as the basis for storage system databases.

Reel aMounts Reporting Centre will even help in generating shelf loading plans, providing weight and diameter information for reels.

Purchase order number, date code, MSL, country of origin, serial number...and more.

Define what you want to capture and how it maps to your internal fields.

Creates a unique reel ID for traceability.

Customer defined size and layout.

Over twenty fields can be included in human readable form, bar code (1D and 2D) or both.

Automatically translates supplier part codes to internal codes, eliminating human error.

Labels can include shelf location for fast, accurate put-away.

All data captured can be passed automatically to ERP, EMS and/or WMS.

Generates a compact, but globally unique ID for every reel.

Can be cross referenced to any existing reel ID, serial number or licence plate. All traceability is then possible from either version.

Maintains a complete history by unique reel ID, showing where used, when, what for, who by etc.

Reads and interprets 2D bar codes in both ECIA and ISO15434 formats - even badly constructed ones.

Provides flexible and automatic translation to internally used data and bar codes.

Translates supplier part codes into your part codes.

Allows reels to be trapped based on any combination of part code, supplier and original quantity. Ideal for quarantining faulty or suspect material.

Controls the splitting process, ensuring that both donor and receiving reels are correctly labelled with both part code and traceability information.

Customer defined size and layout.

Over twenty fields can be included in human readable form, bar code (1D and 2D) or both.

Can have multiple label formats to suit point of application.

Monitors the age of each reel.

Warns when a reel is approaching or has passed its use by date.

Identifies compliant and non-compliant material and demonstrates that the correct material was used in any build.

Reel aMounts Reporting Centre reports on all data captured by Reel aMounts - counts, kits, WIP, component usage, inventory, attrition...

Over 200 predefined reports ranging from top level analysis to individual reel traceability. All can be viewed on screen, printed, saved and exported to other formats such as Word or Excel.

Simply double click on a cell in a report to drill-down to related detail reports.

Analysis of attrition by part code and work order allows you to refine purchasing decisions - ensuring sufficient inventory but not overstocking.

Can track country of origin of all material and report on geographic breakdown by value for any work order.

Provides the status of any reel in the plant - part code, quantity, manufacturer, where last used, in our out of kit...

Monitors and reports on recyclable reels received and exhausted to aid with regulatory compliance.

Reel aMounts Reporting Centre is available to any PC, tablet or smart phone in your organisation, world-wide.

Pick and choose what elements you want to implement when. Multiple integration options mean you can fit in seamlessly with existing processes and IT systems.

Works with any combination of placement equipment. Mixed makes and types, or older equipment, are not a problem.

Portable. Easily moved to where it is required. Ideal for line and cycle counting as well as full physical inventory and returns.

Constantly enhanced and now in its thirty-fourth version. Proven world-wide from China to Brazil.

Systems installed thirteen years ago are still using original hardware, which has required only a low-cost, annual calibration.

From a company that specialises only in electronics manufacturing and has 30 years' experience in that field.

Processing millions of reels each year. Available now. Not "vapourware" - to be written once a sale has been made, leaving you as the test site.

You can have any amount of part numbers for the same part. Reel aMounts can even translate between them automatically.

Reel aMounts can handle it.

Reel aMounts can handle it.

Reel aMounts can handle it.

Reel aMounts can also use them, and give you reel histories by serial number.

Reel aMounts can handle it.

Reel aMounts can handle it.

Patented Reel MagicTM technology in Reel aMounts allows for this automatically.

Reel aMounts allows for this automatically.

Reel aMounts allows for this automatically.

Reel aMounts can lead you through the process, label the new reel correctly and allow for any difference in weight automatically.

Reel aMounts can count reels in feeders, even where two reels share a feeder.

Reel aMounts will print them for you and can also read them with our standard scanner.

Reel aMounts can be implemented as a fully portable system on a trolley.

Eliminating errors in counting

Typical reduction in errors in use of equipment – 99.6%.

Eliminating errors in data recording

Elimination of data recording errors – currently 1% of all recording.

Eliminating errors in data entry

Elimination of data entry errors – currently 1% of all entries.

Correct labelling of components

Accurate labelling of all material.

Counting all material - Not just class A

Accurate inventory for all classes of material will eliminate unexpected shortages.

Counting material on the production line

Accurate inventory for material left on the production line.

Fast counting of material during line changeover or other stoppage.

Attrition assigned to correct build where material is kept on the line.

Supporting the move to Supermarkets/Mini-market

Accurate inventory for material stored in mini-markets and line-side supermarkets.

Typical reduction in headcount for counting – 80%.

Accurate recording of attrition

Actual, not estimated, knowledge of attrition for each build.

More accurate material usage forecasting.

More accurate job costing.

Timely knowledge of attrition

Supporting a reduction in attrition.

Reduction in misplaced material

Eliminating loss of material during counting

Loss of material in counting reduced by 100%.

Eliminate delays due to inaccurate inventory.

To your customer, this is really value added.

Reduction in material handling

Improving material flow

Typically improving material flow at counting by 88%.

Speeding pull signals to suppliers

Typical delay in pulling replacement material reduced by 88%.

Shortening delivery times and/or

Widening the circle of "local" suppliers

Typical time for delivery of replacement material reduced by 35%.

Typical area in which to choose local suppliers increased by 151%.

Reduction in floor space for counting equipment

Typical saving in floor space for counting equipment – 80% or better.

Reduction in floor space for material waiting for counting

Typical saving in floor space for components awaiting counting – 80% or better.

Material availability improved by 800%.

Aid in increasing inventory turns.

Labelling reels with lead free logo / text.

Recording RoHS / lead free status of issued material.

Elimination of rework costs caused by labelling errors when splitting reels.

Identifying moisture sensitive devices returned from production and warning that they must be stored in bags.

Elimination of production delays while parts are baked.

We can demonstrate the Reel aMounts system to you using the Internet.

You will see the actual system in use. This is not a simulation, recording or PowerPoint presentation. This means that we can discuss how you work in your plant and what you are trying to achieve and then explore whether our system can help you, demonstrating exactly how it might work.

You simply need the interested people in a conference room, with a speaker phone and a PC attached to the Internet. To see the demonstration on your PC, all you need is a web browser - Chrome, Firefox, Edge...

Mulrany, Westport, Co. Mayo, Ireland

e-mail: info@seratel.ie

Phone: +353 98 36244

Seratel Limited is registered in Ireland.

Incorporated 1995

Registration no. 236509. VAT no. IE8236509C

Registered office: Mulrany, Westport, Co. Mayo, Ireland

Directors: M. J. Bloor, J. M. Bloor

Seratel - Computer Systems for Electronics Manufacturers - Consultancy and Bespoke Software Development

e-mail: info@seratel.ie phone: +353 98 36244

© Copyright 2017-2025 Seratel Ltd.